We handle the earliest device designs in-house, from structural design to prototype production.

We have also formed a partnership with AMFitzgerald, which is based in the United States, and have established a system to solve advanced problems.

device design

device design

Design

We provide development support from the design stage of MEMS devices to turn product ideas into reality.

Support from device design to simulation.

We provide high-value services through development at our fab and collaboration with university and research institutions.

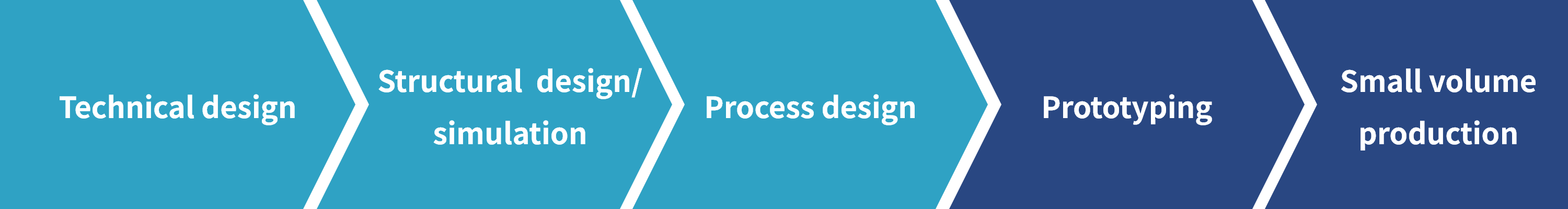

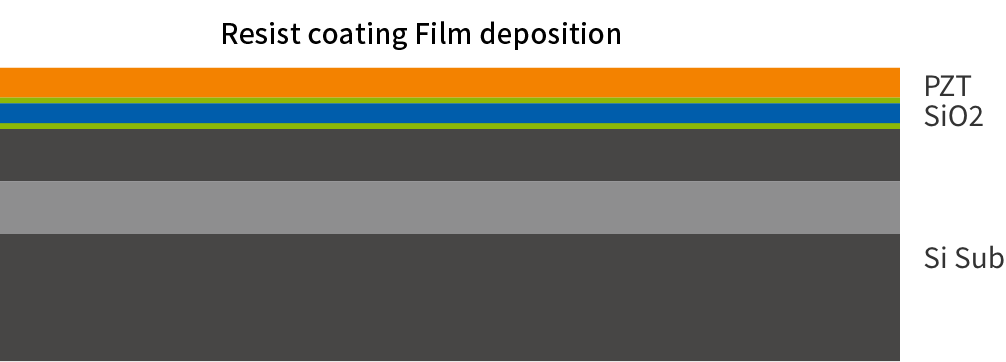

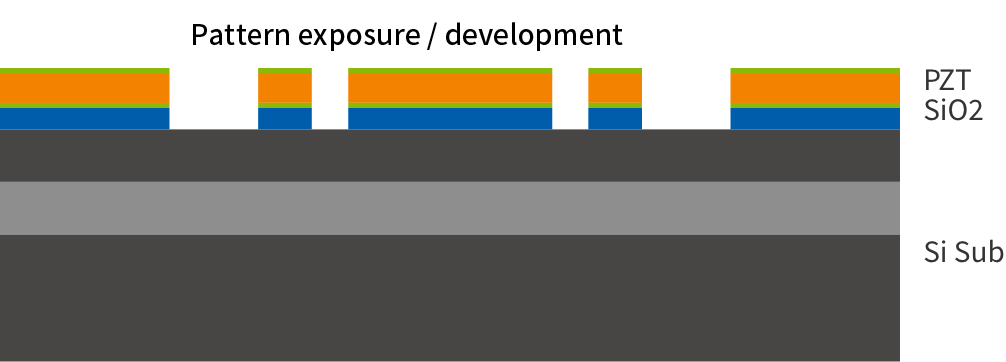

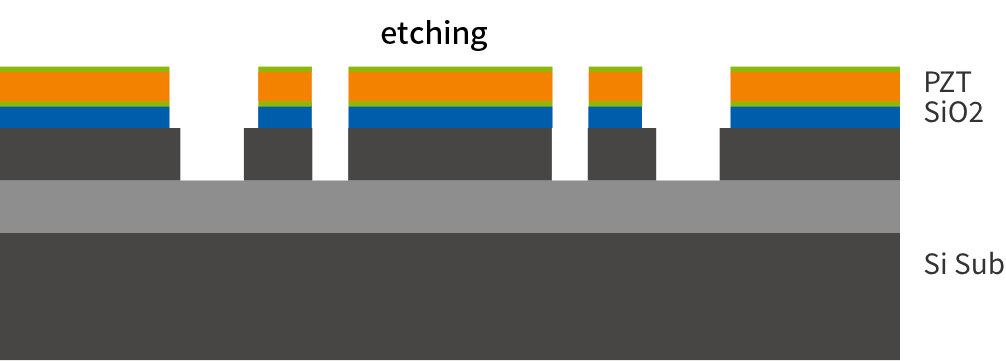

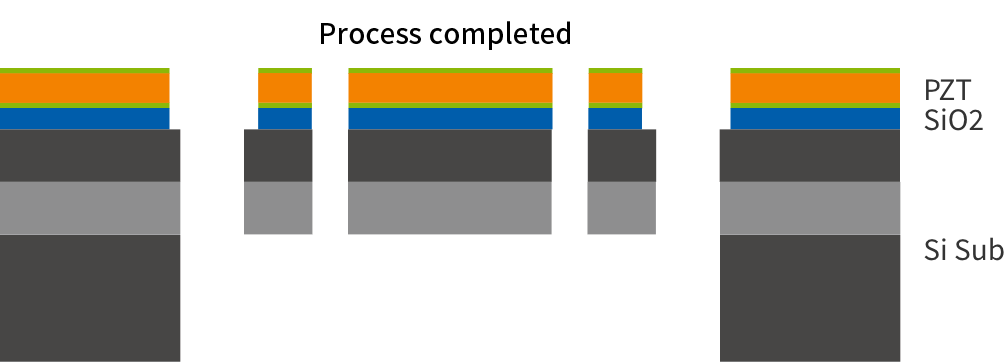

MEMS device design process

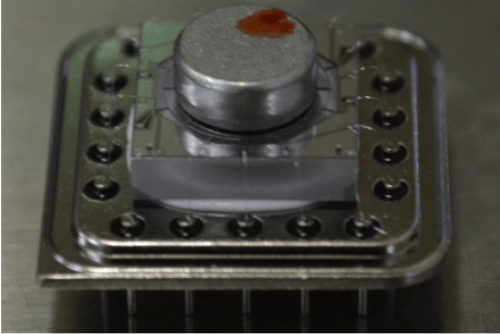

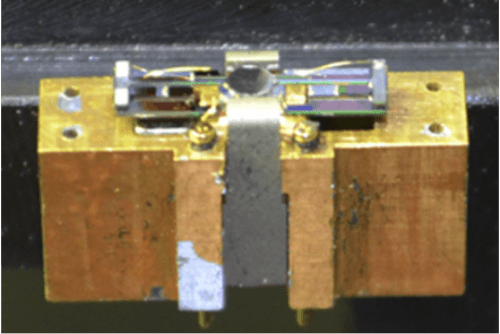

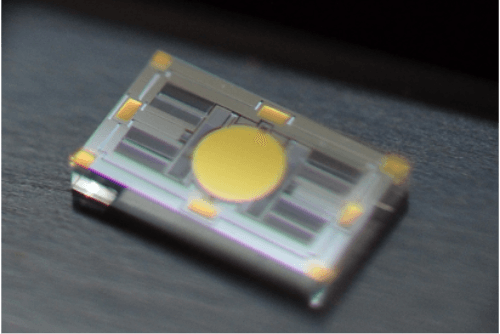

We handle the earliest device designs in-house, from structural design to prototype production.

We have also formed a partnership with AMFitzgerald, which is based in the United States, and have established a system to solve advanced problems.

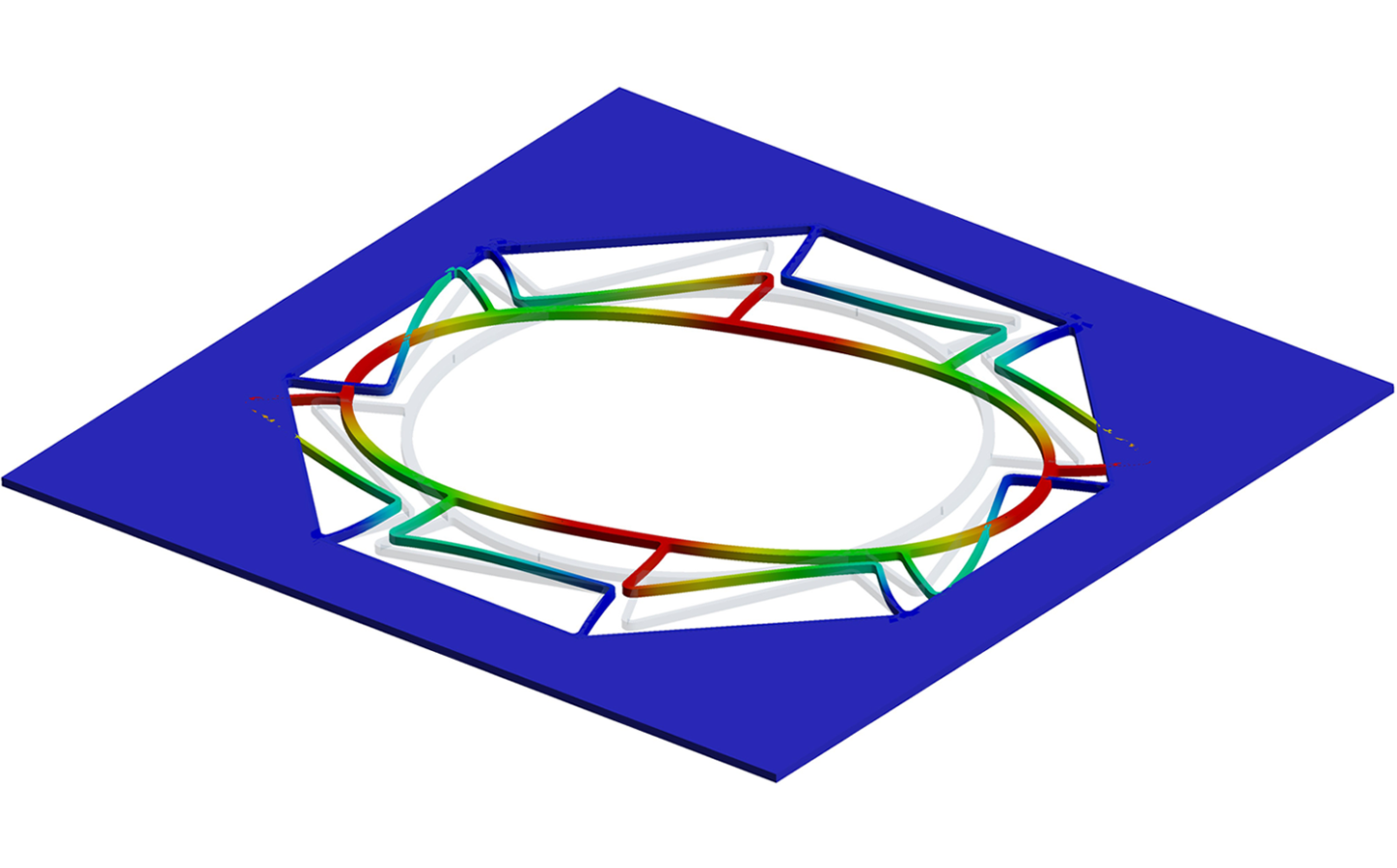

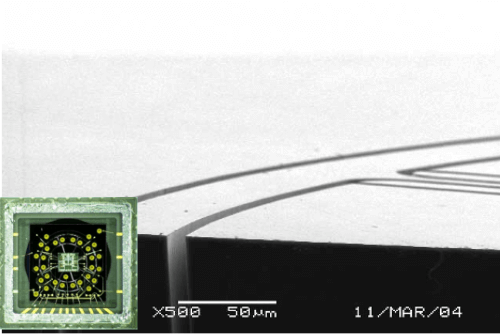

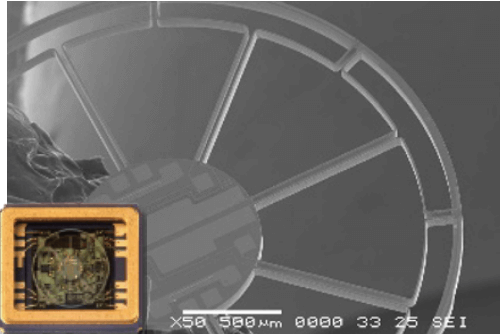

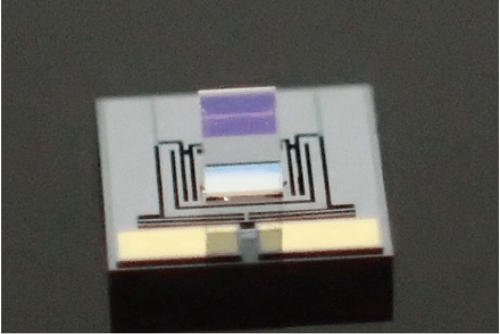

We listen to the customer's requests and support development from the initial structural design. By performing model analysis using FEM (finite element method), we can analyze the behavior of each material against load, vibration, and heat, and derive the optimal structure.

Calculation accuracy can be improved by subdividing multiple elements in a structure and adding each contact point and intermediate contacts between them. By performing strength analysis and vibration analysis, it is possible to identify problems at the design stage in order to realize the product.

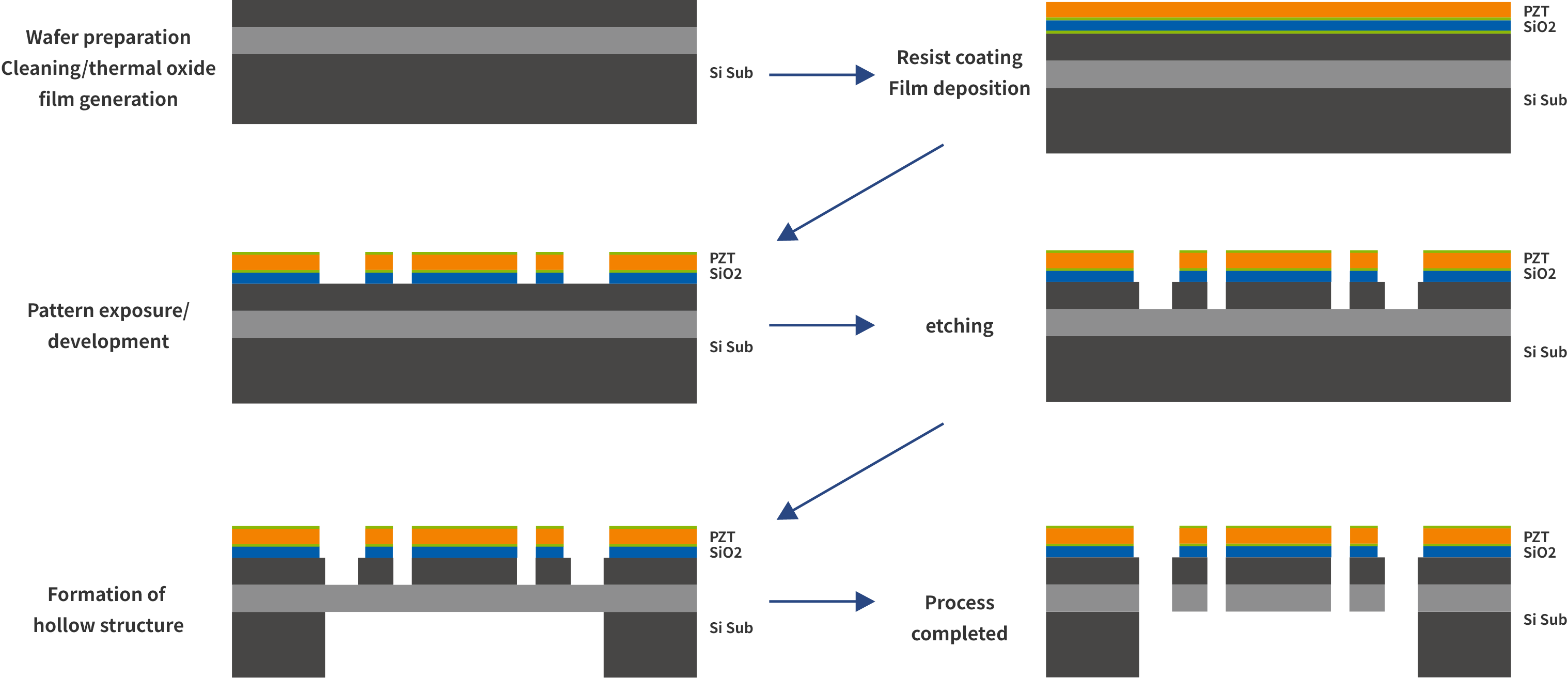

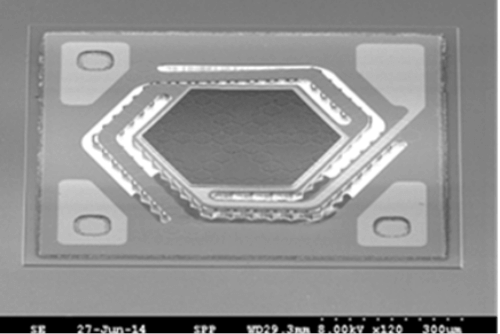

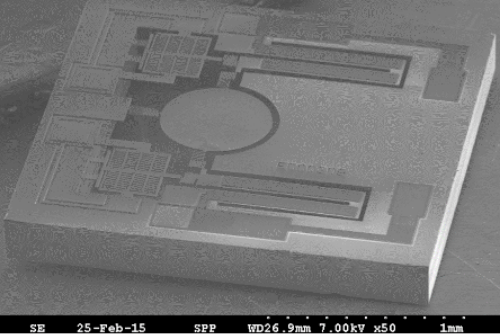

After simulation, we design the device and its fabrication process.

We repeat the process of piezoelectric element formation, film deposition, dry etching, and wet etching to create a prototype MEMS device.

| technology | electromagnetic | electrostatic | piezoelectric | others |

|---|---|---|---|---|

| Sensor design example |

electromagnetic |

electrostatic |

piezoelectric |

Pyroelectric |

| Actuator design example |

electromagnetic |

electrostatic |

piezoelectric |

thermal |