Reasons to Choose us

SPP has a rich history in the MEMS industry. We're one of the few companies that both design and manufacture MEMS tools and MEMS devices. We fabricate a wide range of MEMS devices, spanning electrostatic MEMS to piezoelectric MEMS. And we are one of the world's leading providers of piezoelectric MEMS thin films.

The evolution of MEMS never stops, and its possibilities are infinite. MEMS Infinity, in conjunction with SPP and its other divisions and affiliated companies, embraces the challenge of what is possible with MEMS. Let's move into the future of MEMS together.

1992

MEMS Manufacturing equipment, IX200 on sale.

User's labo was founded.

IX200 were supplied for MEMS development inside and outside of the company.

Fundamental study on MEMS device started.

1995

Si DRIE equipment on sale

●Equipment development

SPP Technologies Co., Ltd.

1998

Micromini accelerators were on manufactured and on sale.

●Device development

Sumitomo Precision Products

1999

Joint venture with BAE Systems in UK was founded for manufacturing and sales of MEMS gyroscope

●MEMS Foundry

SILICON SENSING

2009

Launch of inertial system attitude angle detector (AMU)

Inertial Systems Division

2023

Establishment of new organization MEMS∞(infinity)

Started a business that responds to customer requests while evolving MEMS technology

MEMS∞

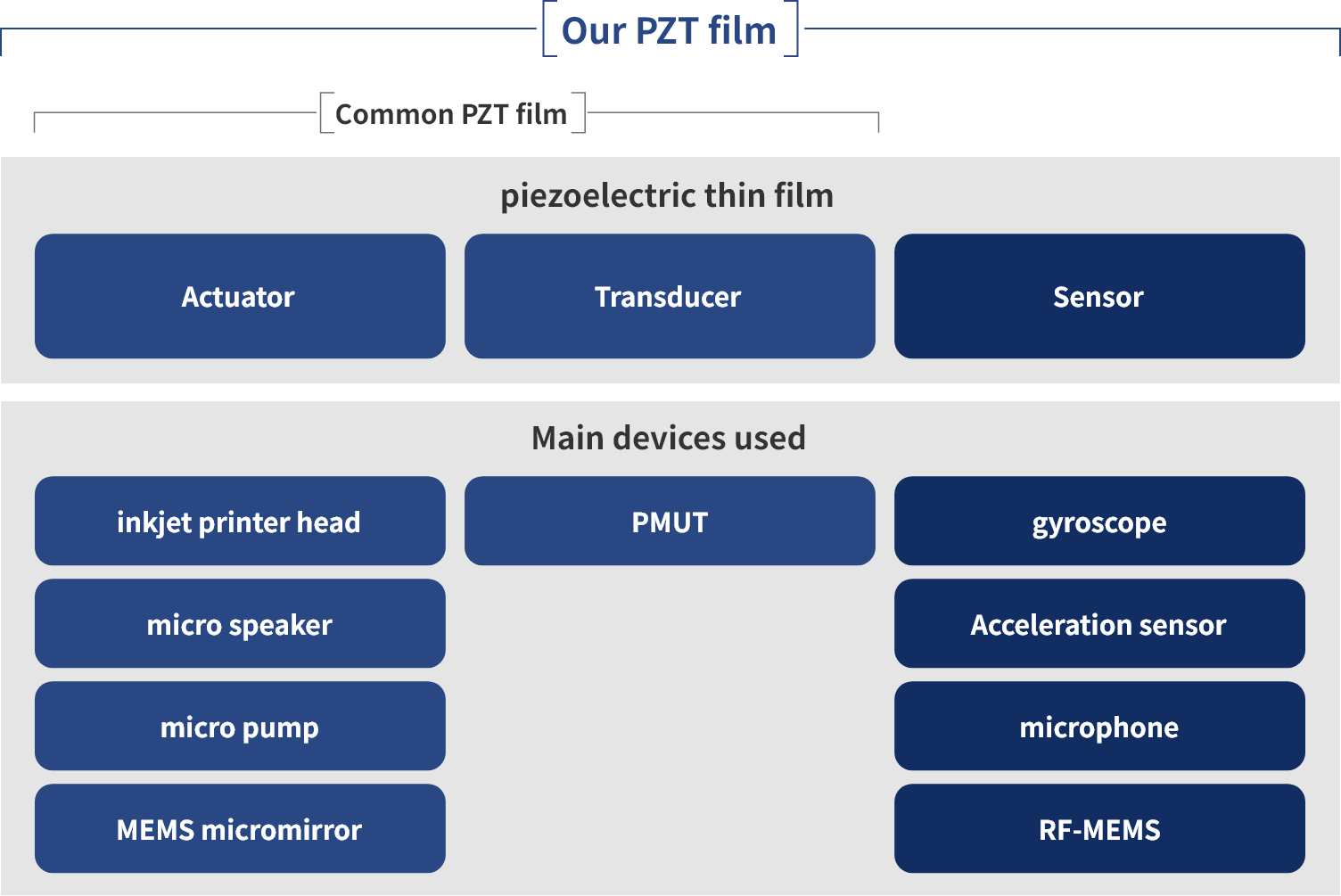

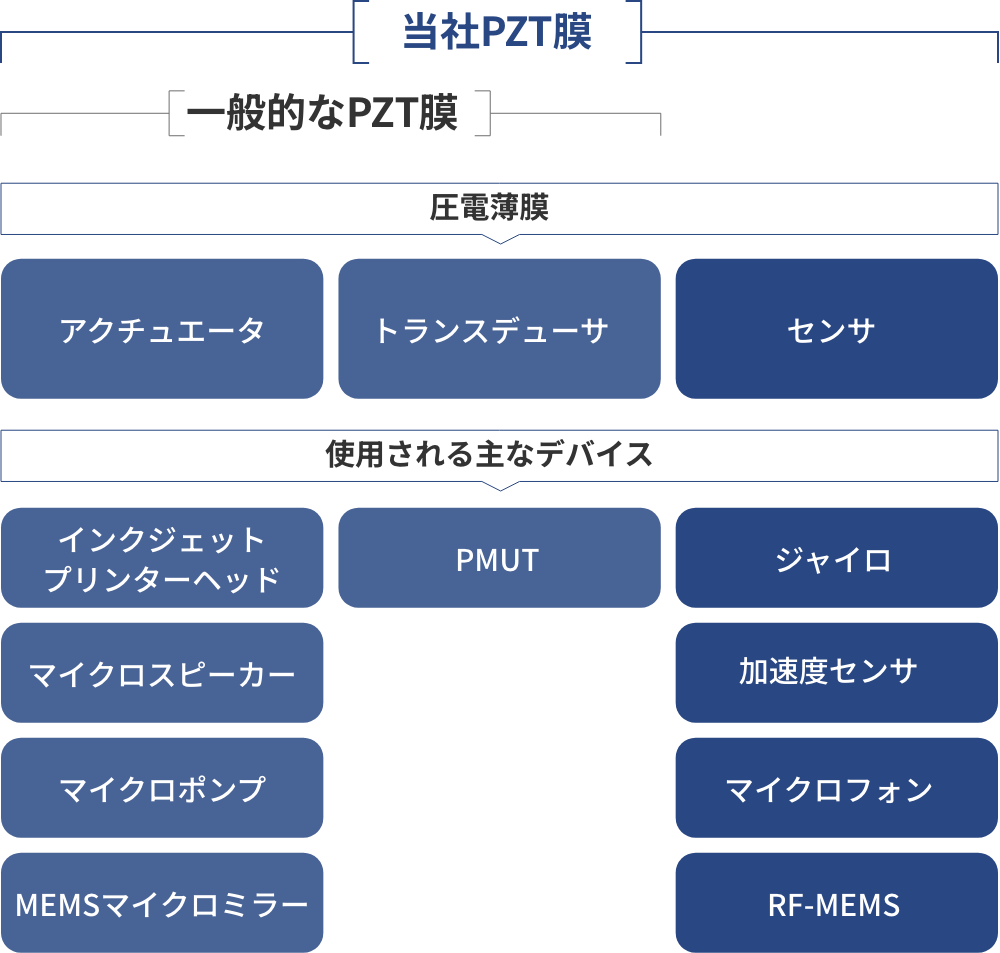

Services that meet customer needs from Film deposition to MEMS device processing are based on the PZT thin film that has been mass-produced in the CRM/CMS series of gyroscopes developed by our company and mass-produced and sold by our affiliated company Silicon Sensing Systems. provide

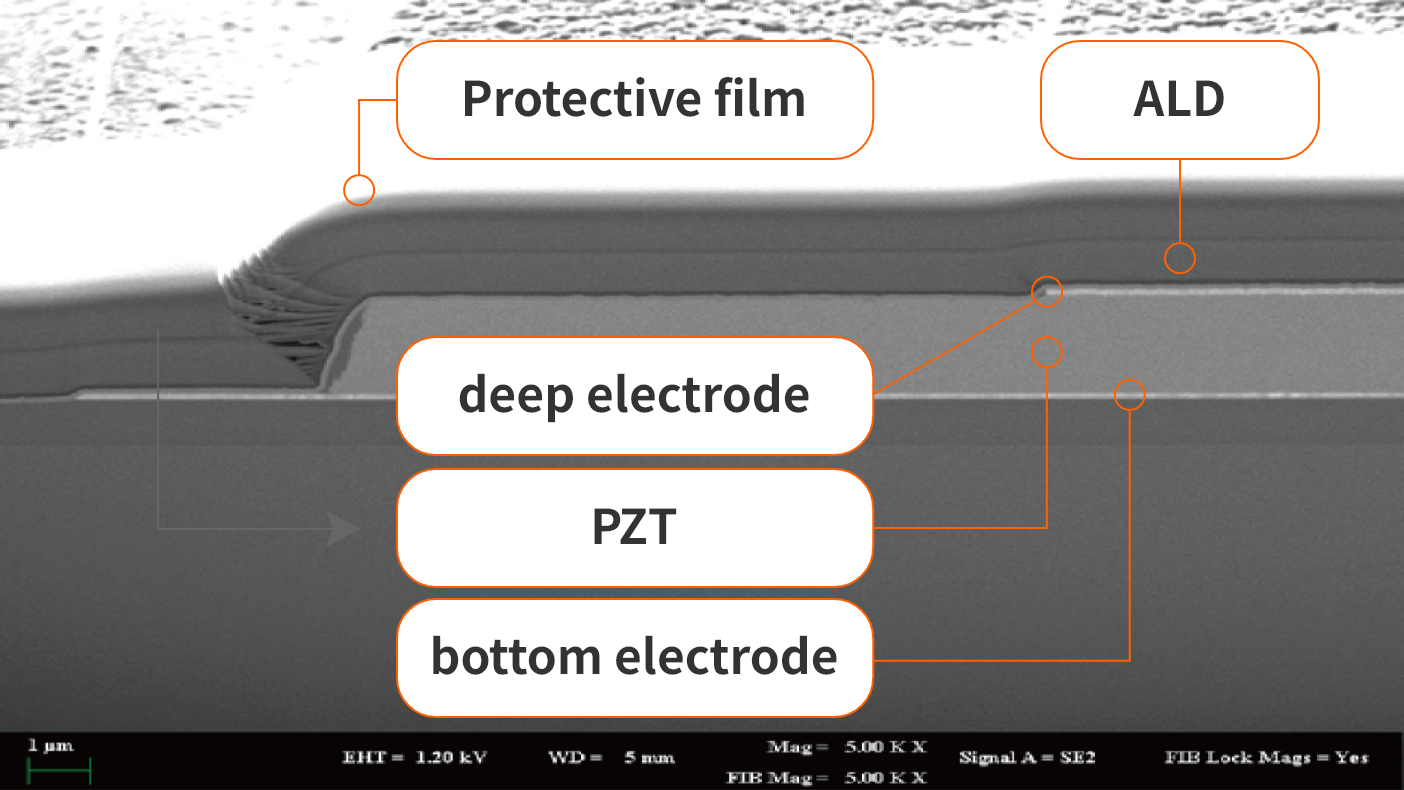

While maintaining the characteristics of the PZT film, we have adopted an ALD film to ensure long-term reliability, which is an issue for MEMS actuators.

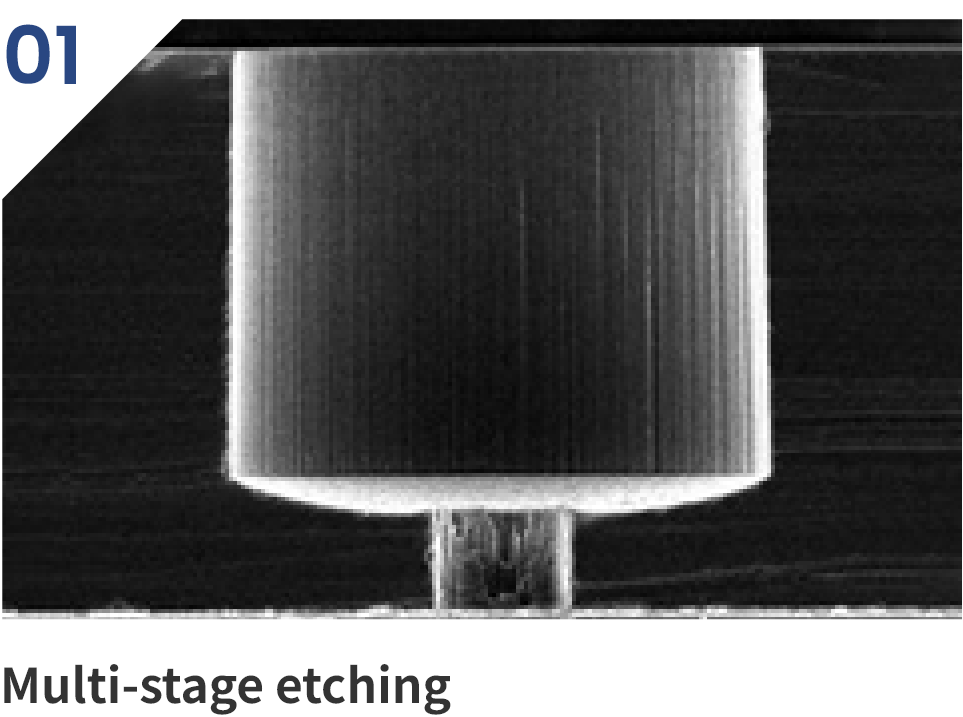

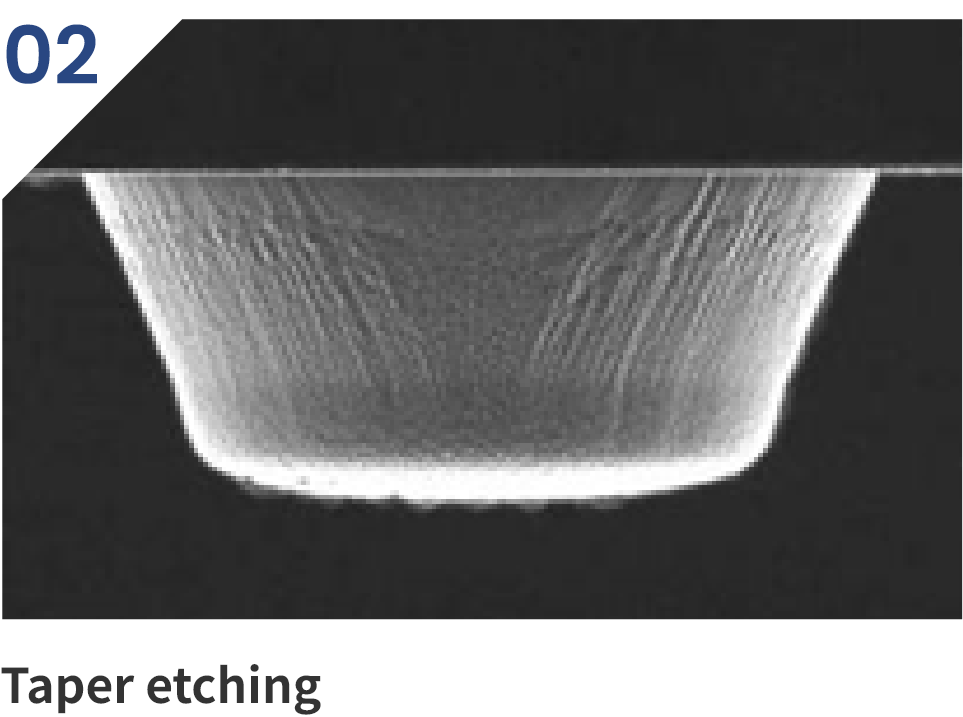

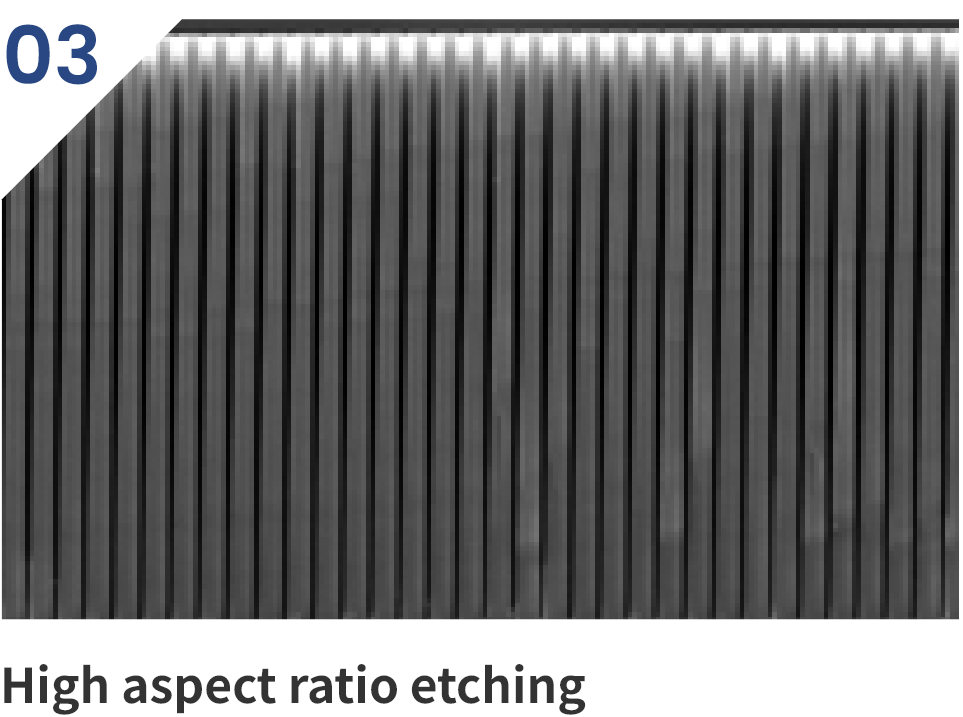

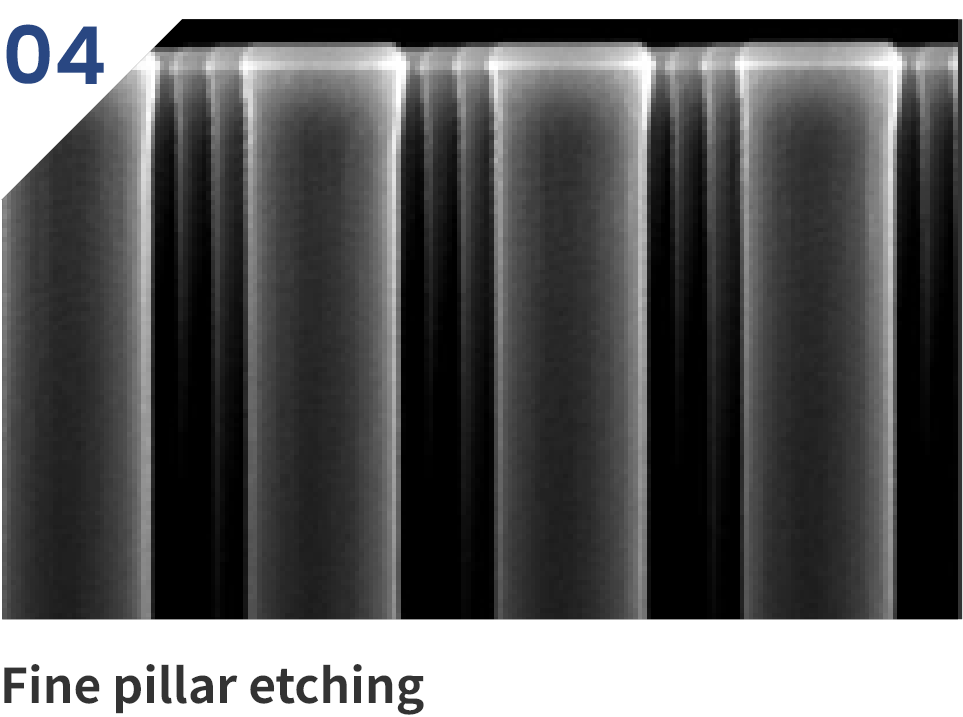

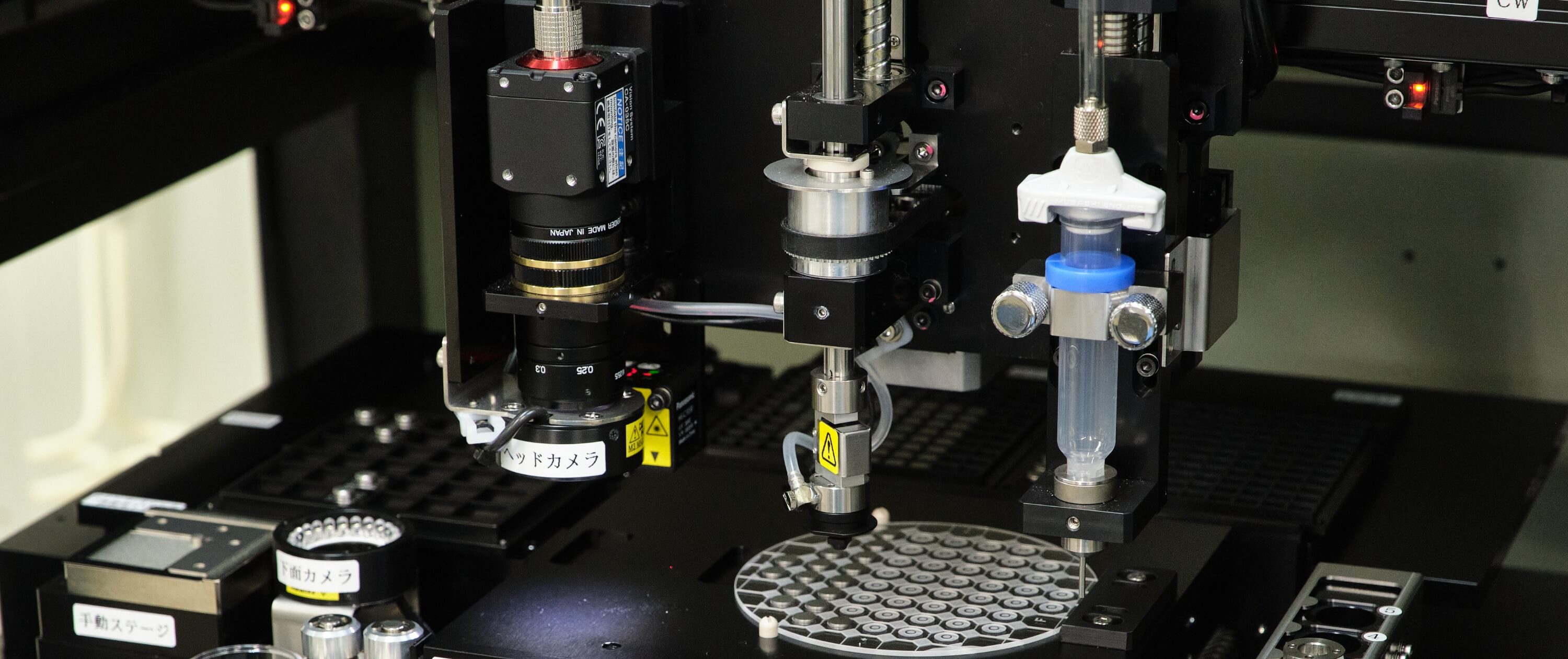

Using Predeus manufactured by SPP Technologies of the Sumitomo Precision Products Co., Ltd. group, which has a proven track record in mass production in MEMS device processing, we have achieved the world's highest level of high selectivity and high etch rate while optimizing verticality, side wall roughness, and CD loss. We realize this and provide highly difficult processing.